Sheet metal work and laser cutting

Proton Engineering manages the entire production flow, from pipe bending, end forming and laser cutting to press braking and welding. We work with both eccentric and hydraulic presses with a pressing force of up to 160 tonnes for flattening and making holes.

Laser cutting is a fast and flexible way of producing sheet metal components to be used in our welded constructions. Laser cutting is often combined with some form of sheet metal working, e.g. press braking, and is suitable for both mass production and the production of prototypes.

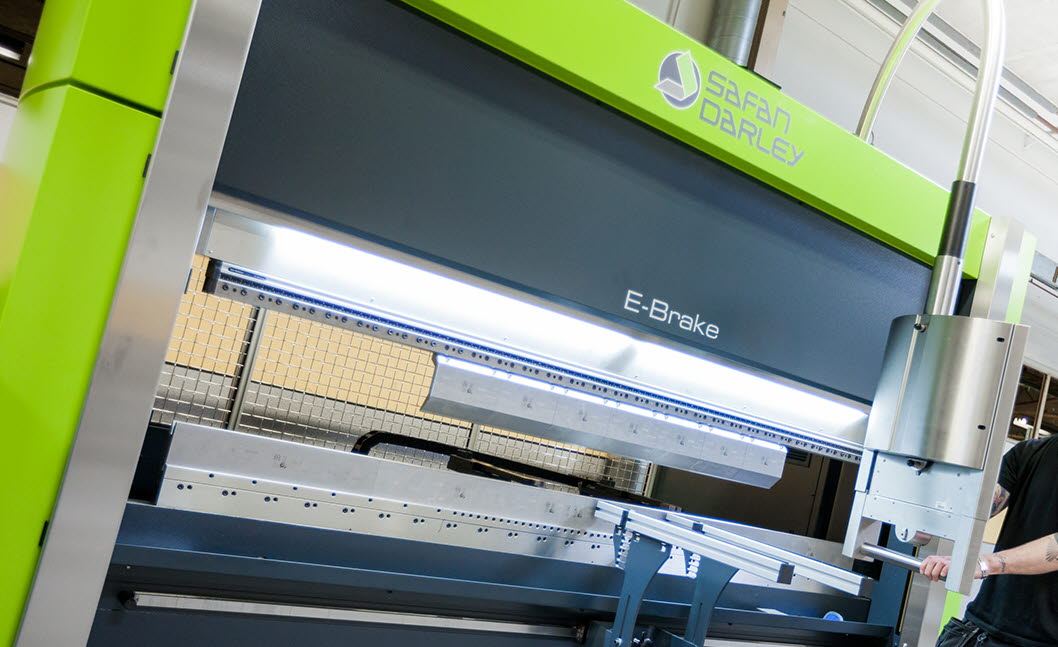

Using a CAD drawing, we create quickly a program for laser cutting. If the sheet metal component is to be bent after laser cutting, the drawing documentation will be prepared as the laser program is created. We work with the latest technology: a 4 kW fibre laser combined with an 80 tonne press brake.

We work with materials such as steel, galvanised steel, stainless steel and aluminium. Laser cutting is ideally performed using nitrogen so the result is smooth cuts without mill scale; this is a requirement if the component is to be painted after laser cutting. When the material thickness exceeds what can be laser-cut using nitrogen, oxygen is used.

Quick facts

We can work with the following materials and thicknesses:

- Steel and galvanised steel up to 20 mm

- Aluminium up to 6 mm

- Stainless steel up to 8–12 mm

- Copper/brass up to 6 mm